PPUH KOMA sp. z o.o.

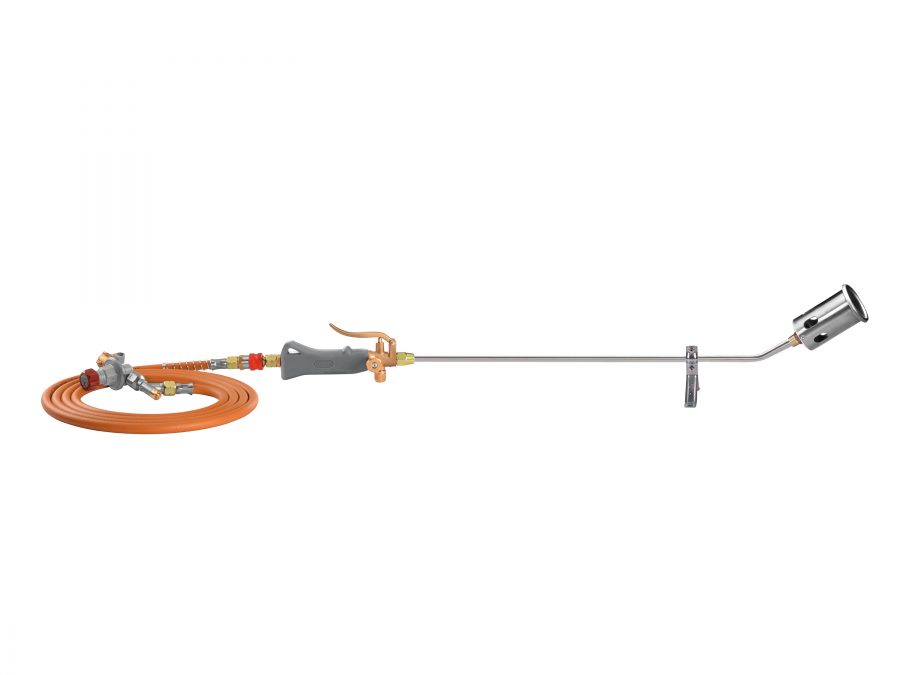

Roofing felt burner

Our professional hot-seal felt burners for roofs, terraces and bridges are designed to make the roofer’s job easier and quicker, while the high quality of the materials ensures long-lasting use.

Our Torches

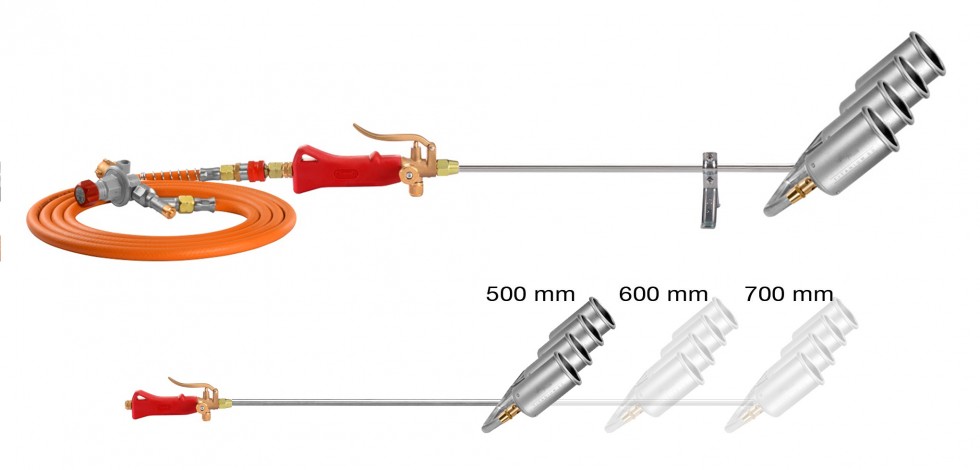

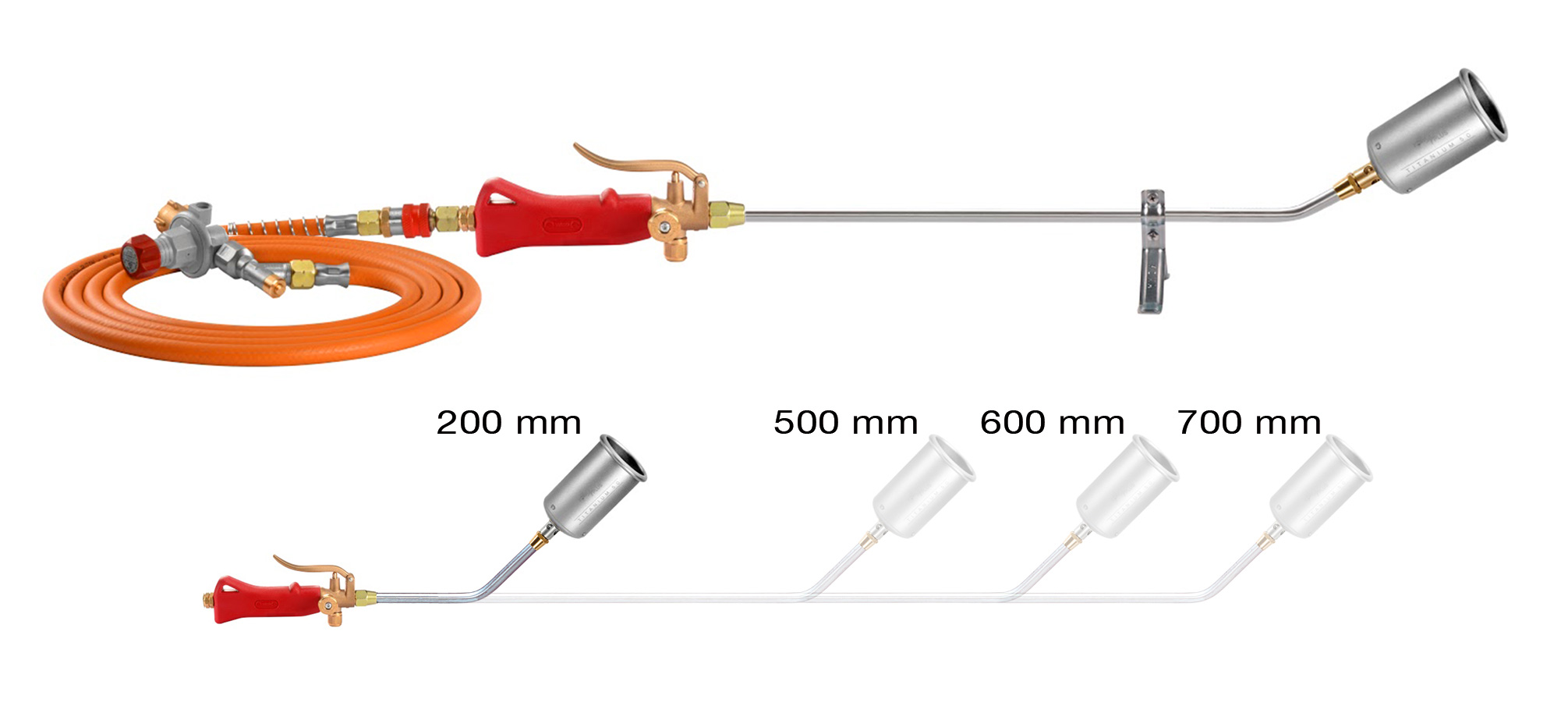

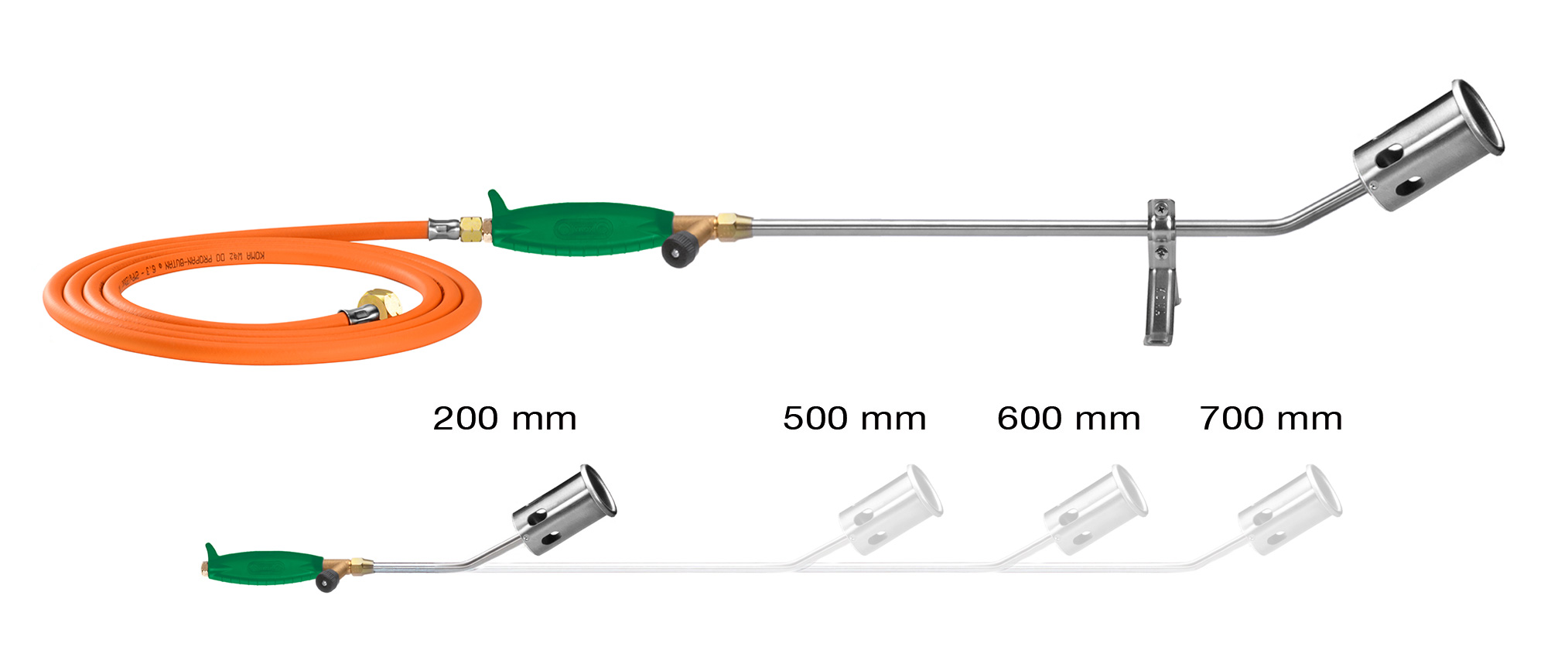

KOMA PLUS TYTAN roofing felt burner series

Ultralight titanium roofing torches for those who particularly value working comfort.

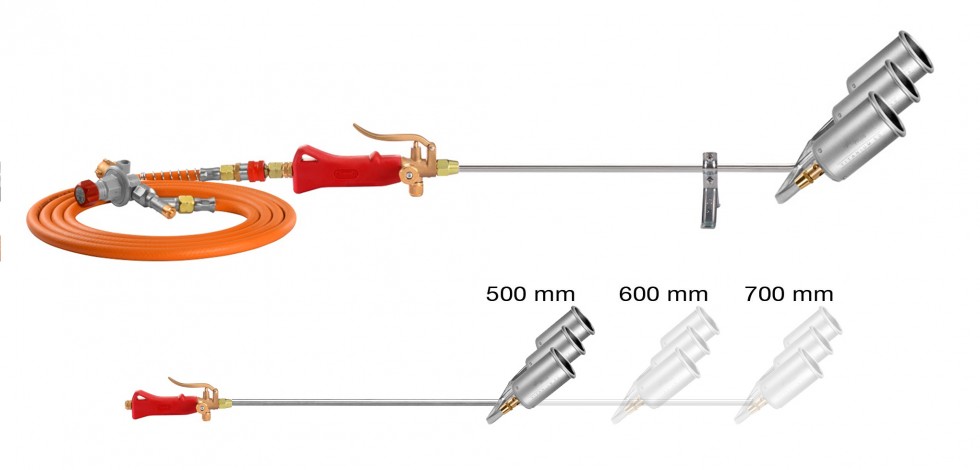

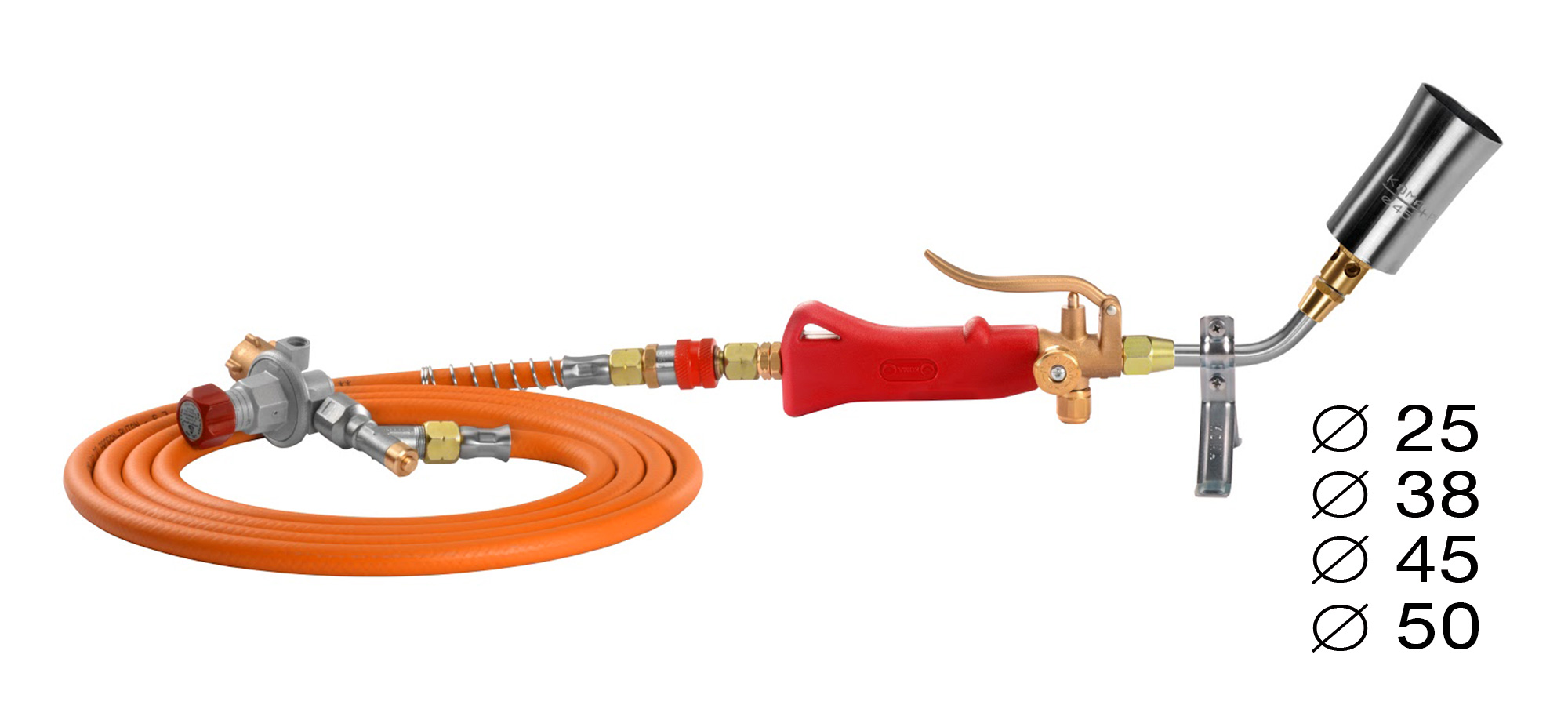

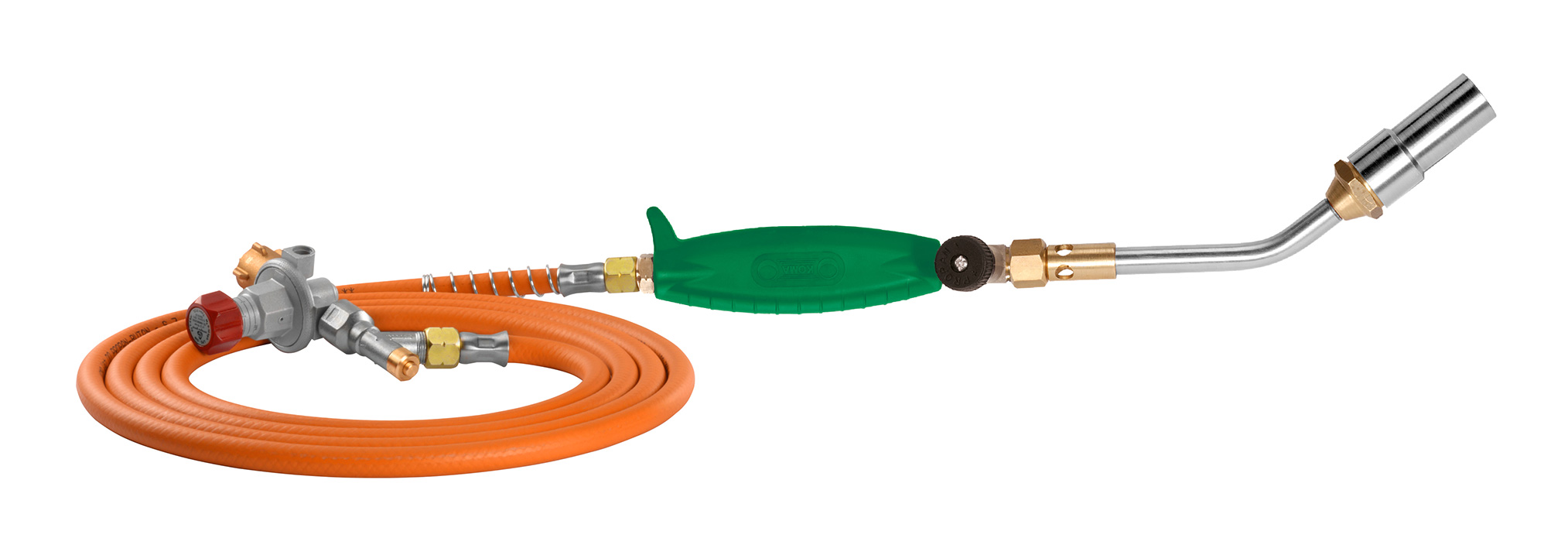

KOMA PLUS tar paper burner series

Tar paper burners designed for users for whom durability, reliability and ergonomics come first.

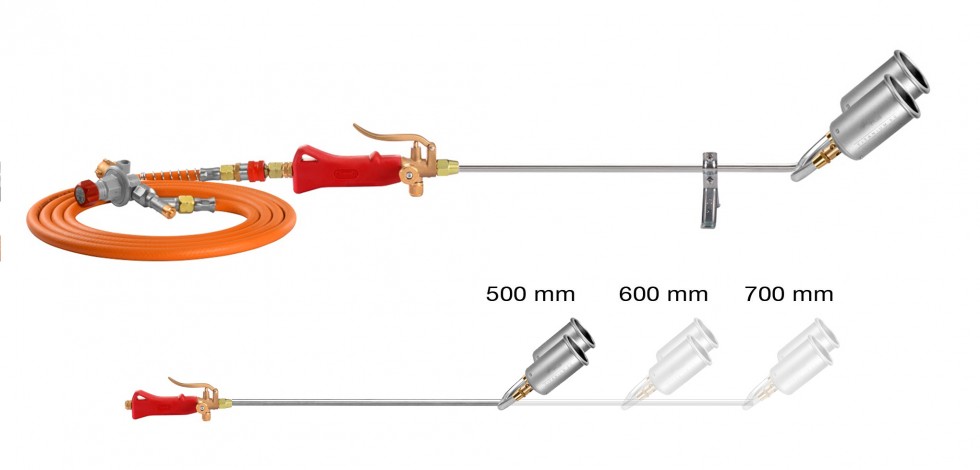

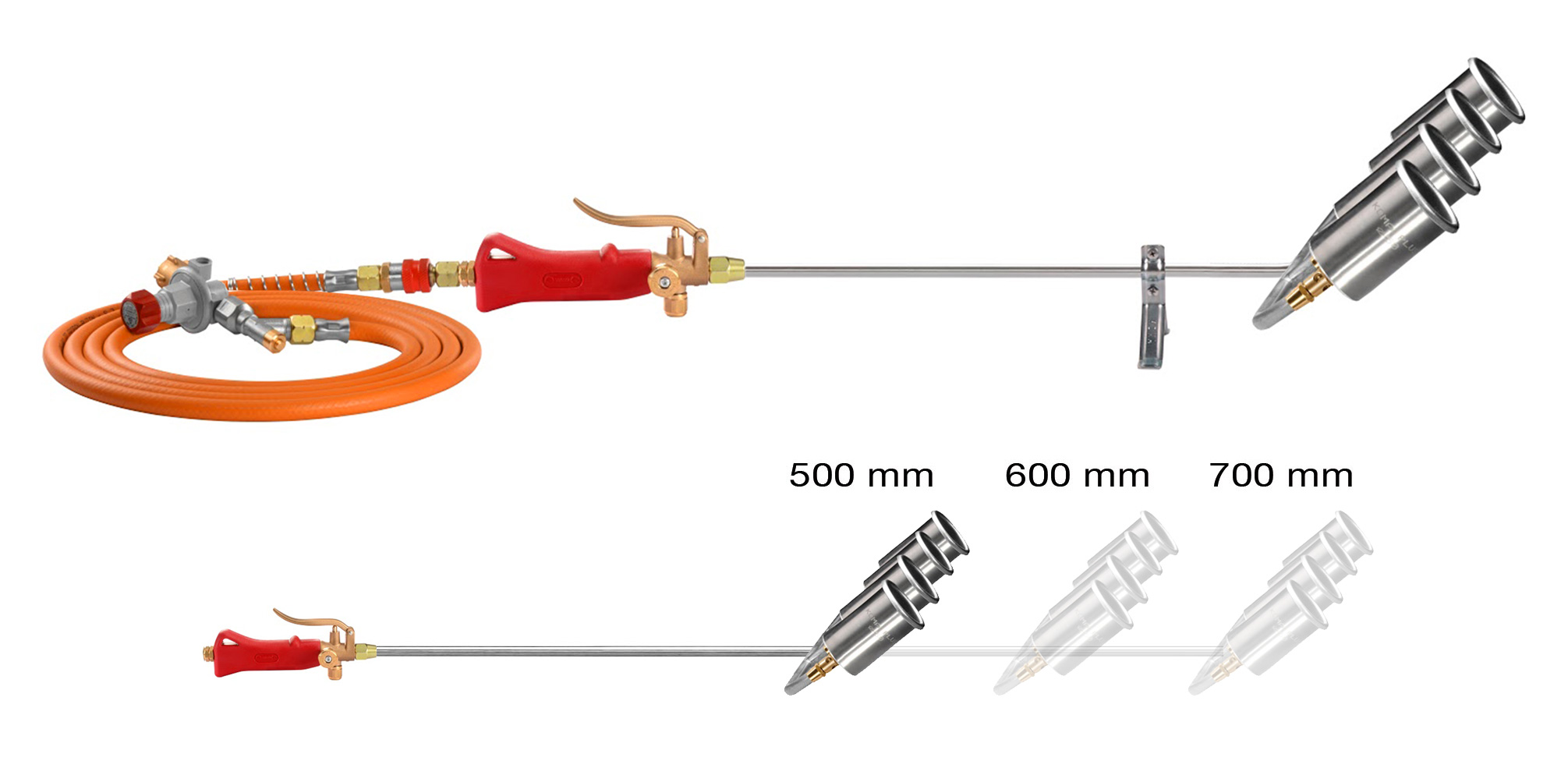

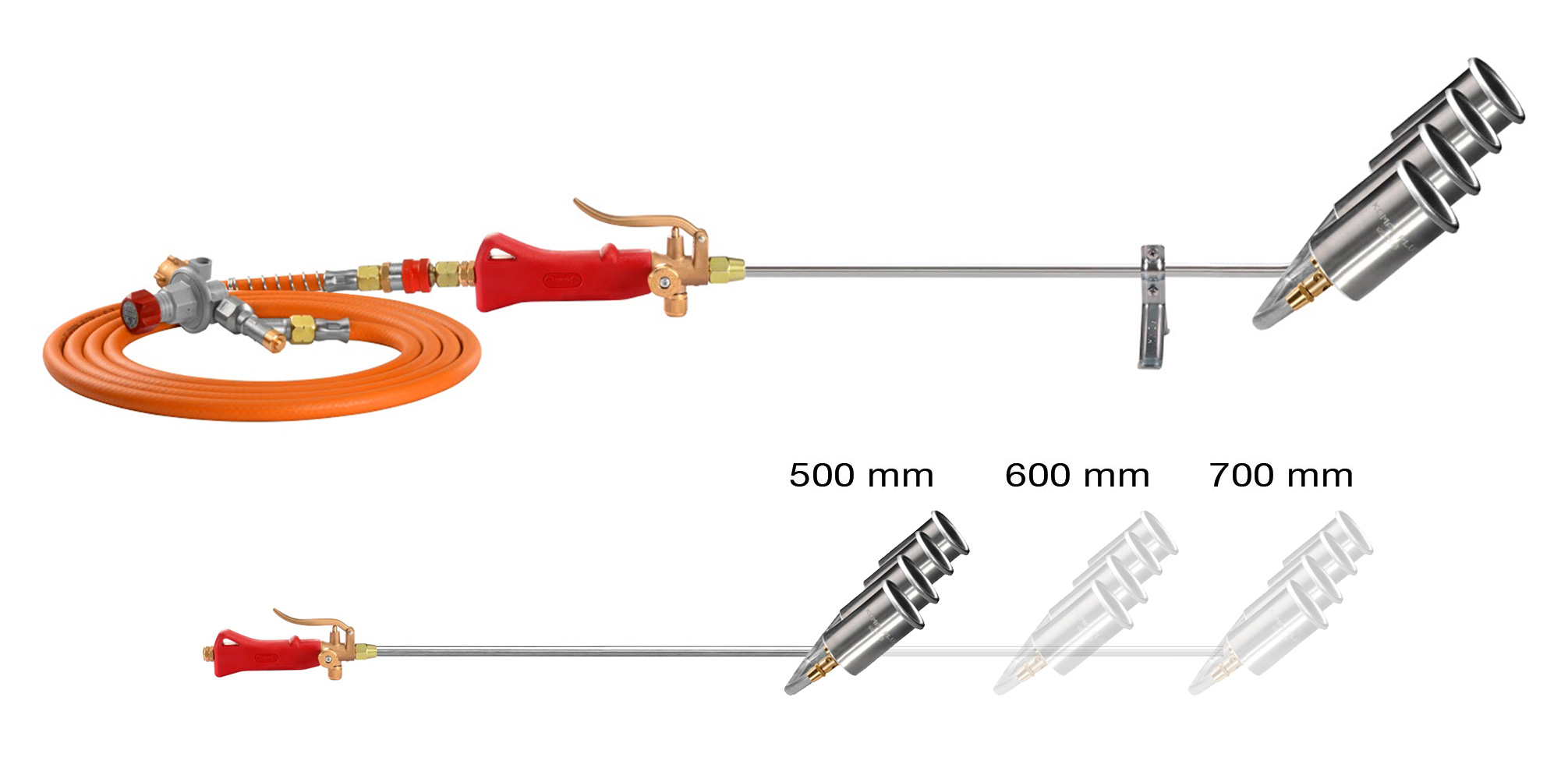

KOMA tar paper burner series

Heat-sealed membrane burners designed for users who expect durability and reliability from their equipment.

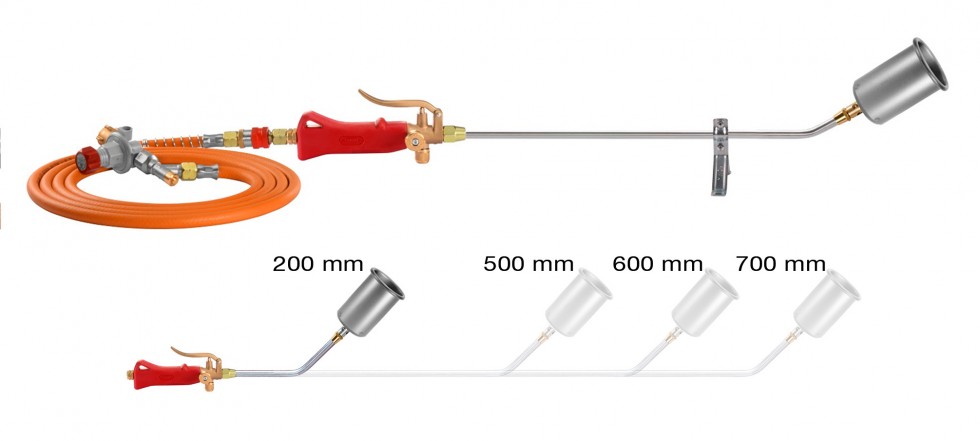

OPTIMA burner series

Multi-purpose burners that are ideal for jobs that do not require long hours of use, e.g.: burning weeds, defrosting floors, lighting barbecues and more

Which tar paper burner to choose?

We recommend burners from the KOMA PLUS line for their durability, reliability and ergonomics. For

standard work, we recommend a burner with an L-700 connector and Fi60 diffuser, while for machining work

machining, we recommend the torch with L-100 connection and Fi38 diffuser. For large and flat surfaces we recommend WP7 or W7 wheel burners

How do you connect a tar paper burner?

The tar paper burner is connected via a hose and regulator to the gas cylinder.

How do you use a tar paper burner?

Operation of the burner is very simple, but the fact that the burner is powered by flammable gas requires

to be handled with care and to observe safety rules.

Do you need a pressure reducer for a tar paper burner?

A reducer is not necessary but is recommended. It allows you to set the operating pressure from 0.25 MPa to

0.4 MPa and for safety reasons, as it shuts off the gas supply in the event of a leak.

How much gas is needed to heat the roofing felt?

KOMA burners consume from 0.4 kg/h of gas (flashing burners) up to 10.8 kg/h of gas (seven-cartridge

burners on wheels). Classic single-line burners consume from 3.3 kg/h to 4.9kg/h of gas

What gas to heat the tar paper with?

Propane or propane-butane

What kind of nozzle for heating the felt?

The most versatile are diffusers with a diameter of 6cm (FI 60)

How many layers of roofing felt for the roof?

We make the roofing felt in two layers. Then we have two types of roofing felt:

layer one of the so-called underfelt, which is glued or nailed to the foundation

the second layer of the so-called top-cover membrane

What are the thicknesses of felt?

Thermally weldable membranes for top-cover membranes are usually of a thickness between

3.7 mm to 5.2 mm, while those used for waterproofing may have thicknesses starting from 3 mm to 5 mm.

5 mm, while those used for waterproofing may be as thin as 2 mm to 5 mm.

thicknesses starting from 2 mm up to 5 mm

Feel free to contact us

We are happy to answer any questions you may have about our roofing burners and accessories.

Mail: [email protected]

Tel: +48 683273307 ex. 6

![]()

![]()

Mail: koma@koma.zgora.pl

Tel: 789 346 889 / +48 683273307 ex. 2

![]()

![]()

Mail: [email protected]

Tel: 510 817 177 / +48 683273307 ex. 1

![]()

![]()

Tel: +48 697722404 / +48 683273307 ex. 3

ISO 9001:2015 certification

The Quality Management System mobilises us to continuously improve our products and services. The level of customer satisfaction is a priority for us, so we strive to provide them with products that meet their expectations and are tailored to their needs.

30 years of experience

Over such a long period of time, we have ensured that our products are characterised by durability, quality, modernity and aesthetics.

ISO 14001:2015 certification

We are aware of the environmental constraints associated with our activities and are committed to the rational use of the planet's natural resources.

Nasza praca jest naszą pasją , dlatego pracujemy z przyjemnością i dużym zaangażowaniem. W oczywisty sposób przekłada się to na jakość naszych produktów i efektywność działania.

PPUH KOMA SP. Z O.O.

PRODUCENT PALNIKÓW GAZOWYCH

I URZĄDZEŃ DLA PRZEMYSŁU MIĘSNEGO